Water injected air compressors DH series

One stage water cooled oil-free screw air compressors fixed and variable speed

From 15 to 110 kW, D15H– D110H RS

D15H– D110H RS CompAir series provide 100% clean compressed air which meets strigent quality standards. The DH series contains absolutely no oil anywhere in the compressor and has been certified ISO 8573-1 Class Zero (2010) and silicone free.

Lubrication, cooling and sealing of the compression element is carried out by water fed through a closed system containing reverse osmosis technology. Therefore, it is the ideal choice for food & drug manufacturing, packaging, petrochemical and power generation industries.

The only Pure Air air compressor in the market with no trace of oil

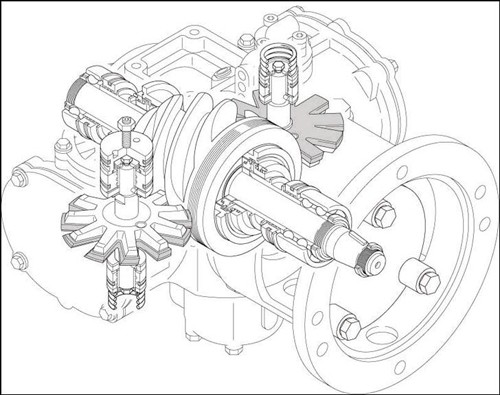

- Compression element is single stage 1:1 connected with IE3 class motor to maximize efficiency and minimize space requirements (~ 20% less m²) of the complex

- High quality water injection lubricates, cools and seals the compression process, maximising efficiency

- No gearbox means no need for associated oil lubrication

- Low axle loads and low rotational speeds of just 750-3700rpm make this series the most reliable and simplified

- The series can be provided with Allen Bradley inverter for adittional energy saving

- Remote controll via iConn ensures reliable fuction 24/7

- Fully packaged and silenced enclosure reduces noise and simplifies installation

Extremely low risk and of minimum maintenance demands air compressors!

The unique design achieves lower speeds combined with lower operating temperatures - both resulting in high efficiency and reduced component wear. Using a single-stage, direct-driven motor without gears or belts, maximises efficiency. Limiting the compressed air to the application demand with regulated speed ensures that no energy is wasted.

With exceptionally low running temperatures of less than 60°C near isothermal compression is achieved. This also eliminates the need of an internal aftercooler and associates power consumption reducing pressure drop to the minimum.

The tried and tested reverse osmosis filtration provides high quality purified water to lubricate, seal and cool the compression process. Using a permeate pump the water required is reduced to a minimum.

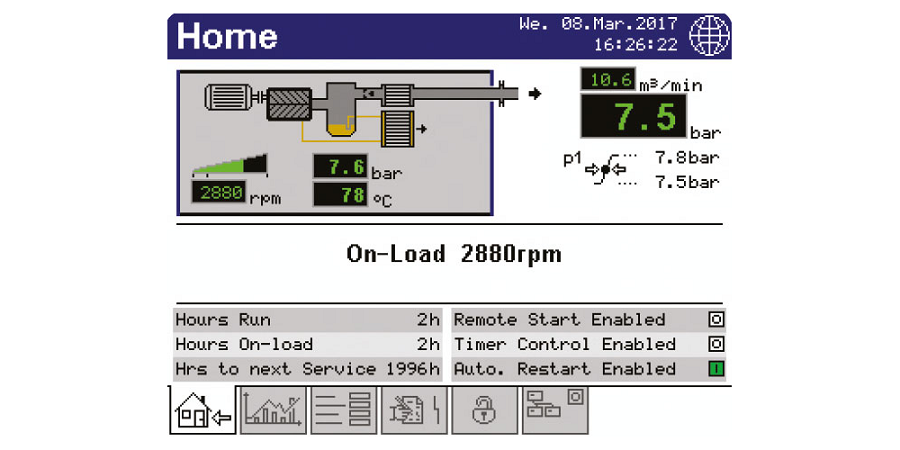

Delcos XL innovative touch screen compressor controller

The Delcos XL with its high resolution touch screen display is extremely user-friendly and self-explanatory. All functions are clearly structured in five main menus and are intuitively visual. The multilingual Delcos XL control system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, which is essential for reducing your running costs

Features & functions

- Delcos XL Controller available in Greek language

- Home Page - instant overview of the compressor status

- Diagrams for better visual imaging of values

- Real Time Clock - allows pre-setting of compressor starting/stopping

- Second Pressure Setting

- Integrated Cooling and Dryer Control

- Fault History Log - for in-depth analysis

- Remote Control via Programmable Inputs

- Auto Restart after Power Failure

- Optional Base Load Sequencing

- SD Card - stores several run characteristics

- RS485 - Modbus RTU