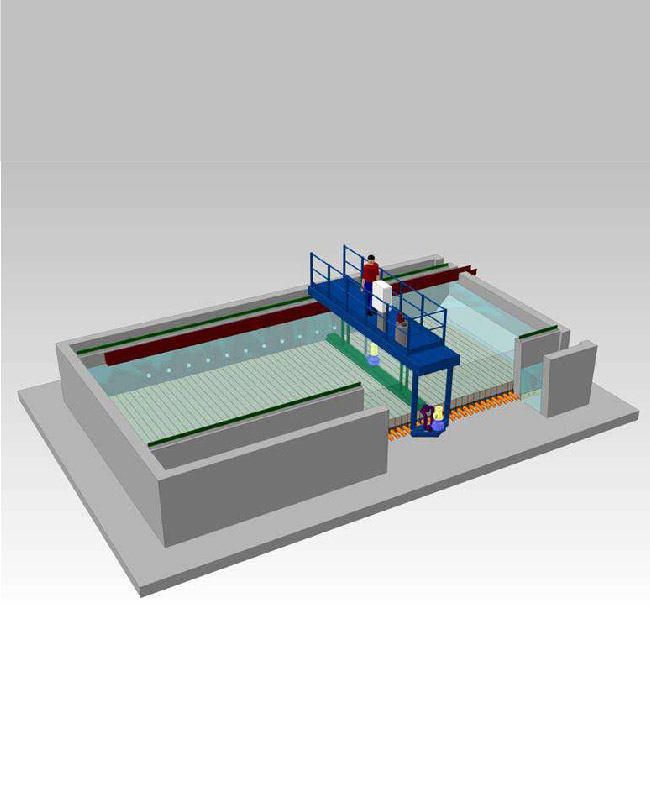

Automatic gravity granular media filter of FCA type

Automatic gravity granular media filter

This type of filter has been successfully applied (over 30 years) in the treatment of potable water and industrial process water for turbidity reduction.

During the past 10 years, this type of filter has acquired wide acclaim and acceptance for its successful operation and performance in the treatment of municipal and industrial wastewater.

Today the FCA filter is recognized as an efficient, cost competitive, simple, energy saving alternative to conventional type filters.

Features

- High reliability due to simple design, high quality materials, corrosion resistant coatings

- Low maintenance with all drives pumps, motors and bearings located for easy access

- Adaptable design utilizes cast-in-place concrete tanks; single media sand, dual media sand and coal or granular activated carbon

- Full automatic system - no operator required

- High filtration efficiency (typically 70-90% SS reduction in domestic sewage)

- Low operating costs (40% reduction in electric consumption to conventional filters)

BASIC OPERATION

The FCA simultaneously filters water during backwash. The filter bed is divided horizontally into independent filtering cells. Inlet water continuously flooding the bed gravity flows through the media and exits, while simultaneously a filtering cell is backwashed under two pumps and a hood suspended below the traveling carriage. During backwash, carriage and attached hood move slowly and continually over the bed, consecutively isolating and backwashing each individual cell. A backwash pump draws filtered water, backwashing one cell by pumping water back through the effluent port. A washwater pump picks up washwater collected in the hood and discharges into the washwater trough. Cells not under the hood continue filtering. Backwash cycle starts whenever head loss occurs or, if desiderate, after a pre-selected time cycle.

FCA APPLICATIONS

Industrial filtration

Solids removal

Process makeup water turbidity reduction

Chemical precipitate removal

Toxic chemical reduction

S.S., BOD, COD, TOC reduction

Municipal water filtration

Turbidity reduction

Color reduction

Trihalomethane removal

Organics removal

Iron and mineral removal

Taste and odor control

Municipal wastewater filtration

Suspended solids reduction BOD, COD, TOC reduction