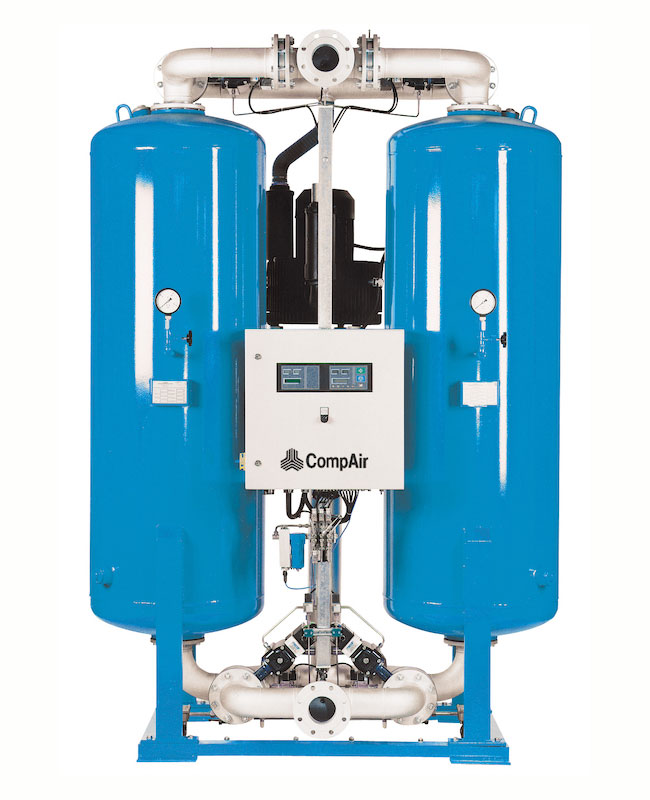

Desiccant dryers for compressed air

CompAir offers a range of high efficiency heatless and heat regenerative compressed air dryers for the removal of water vapour from a compressed air supply. Adsorption compressed air dryers remove moisture by passing air over a regenerative desiccant material, which attracts and retains the water vapour molecules. The term pressure dew point refers to the temperature at which water condensation will occur, a typical pressure dew point specified for an adsorption dryer is -40°C which prevents corrosion and inhibits the growth of microorganisms.

The CompAir A-Series dryers use the heat-less, or PSA, method to regenerate the adsorbent material. These are the simplest adsorption type available and have long been the choice for many industries and applications. Reliable and cost effective and for small to medium flow systems, these are often the only viable technology available. Modular versions such as the A-Series are an even more reliable, smaller, more compact and lightweight solution. They can be installed in the compressor room or at the point of use.

Compared to traditional twin tower dryer designs, the CompAir compressed air dryer’s unique modular construction is typically a lot smaller and lighter than comparable twin tower desiccant dryers. Providing a simple to install and easy to maintain design which is fully corrosion protected and supported by numerous international standard approvals.