info@michos.gr +30 210 6774 280

PRODUCTS - Blowers

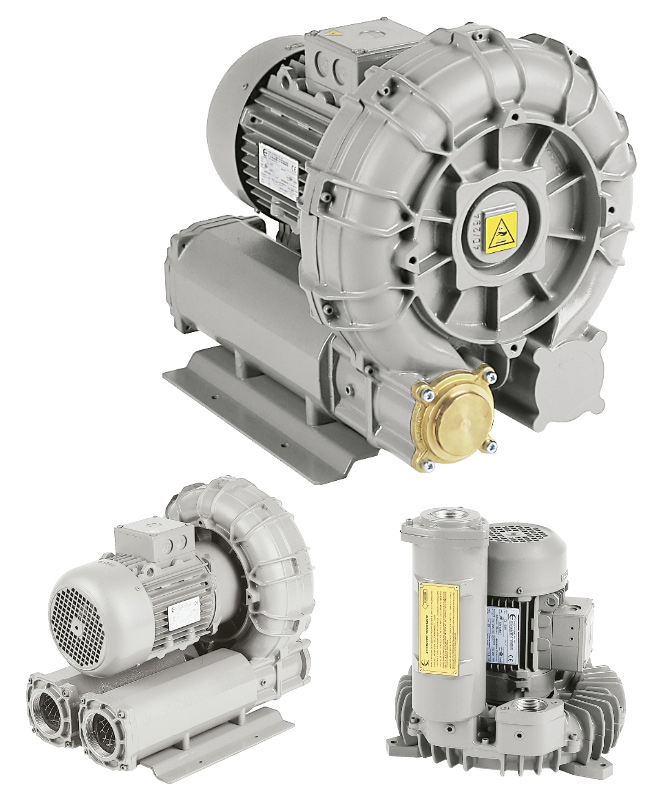

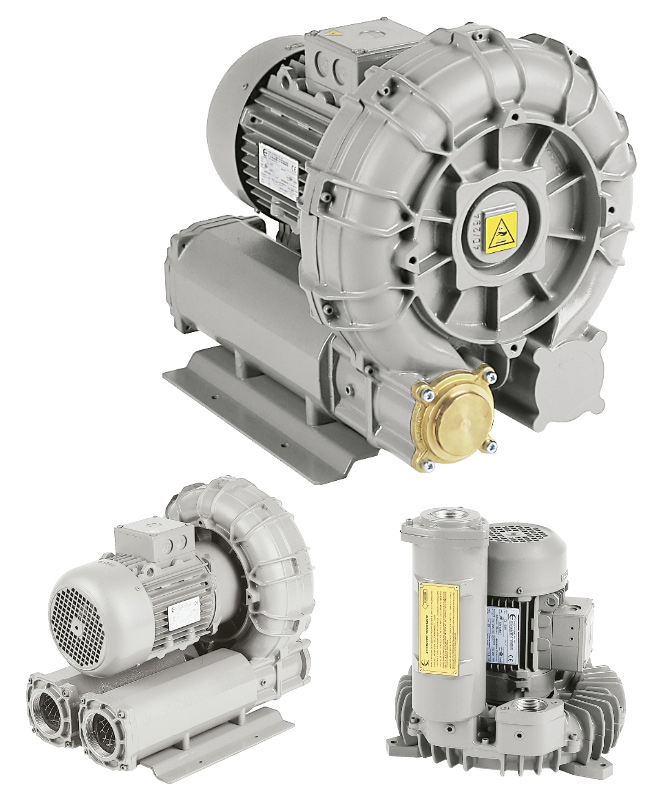

Side channel blowers CL series

Side-channel oil-free blowers

Suitable for applications requiring significantly higher pressure and vacuum than centrifugal fans.

- Pressure up to 800 mbar (g)

- Vacuum up to 450 mbar (a)

- Flowrate up to 2,100 m³/h

Unique advantages

- Oil-free air at the discharge

- Easy and simple installation

- Smooth and vibration-free operation

- Small space requirements

- They do not require lubrication and maintenance

- Special explosion-p for ATEX biogas

Construction

The blower housing is made of EN AB 46400 explosion-proof aluminum alloy and the shaft of high strength C45 EN10083-1 steel. The rotating parts do not come into contact with the housing, there is no friction and no lubrication of the machine is necessary. Consequently, the gas leaving the machine does not carry any particles and is completely oil-free.

Principle of operation

The side channel blower or exhauster increases the pressure of the aspirated gas by the creation, in the peripheral toroidal channel, of a series of vortexes caused by the centrifugal thrust of the impeller. While the impeller is rotating, the vanes force the gas forward and, because of the centrifugal thrust, outwards, producing a helical motion. During this motion, the gas is recompressed repeatedly with a consequent linear pressure increase along the length of the channel.