APPLICATIONS - Food & Beverage

We cover a very broad range of applications in food, meat & poultry industry, dairy, fruit & vegetable processing, pasta, flour, bakery, sugar & confectionery, vegetable oils, soft drinks, beverages, drinks, etc. Our blowers, our vacuum pumps, our air compressors and our special pumps support the most critical stages in the raw material handling, production, packaging and distribution of the finished product.

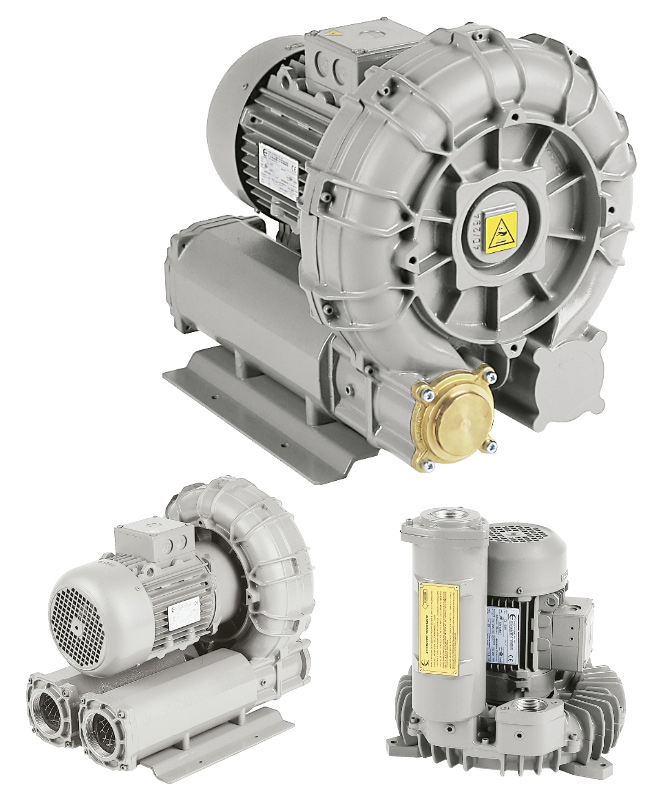

Pneumatic conveying of bulk materials

Any pneumatic conveying of bulk materials (flour, semolina, sugar, powder, etc.), in pressure or in vacuum, is done by lobe blowers, screw blowers for higher pressures and side channel blowers in smaller scale applications. Pneumatic transport makes it easy to move, mix and dose bulk materials over long distances, with fully automated systems that do not pollute the working environment.

Concentration and evaporation systems

By means of liquid ring vacuum pumps or multistage vacuum systems, boiling under vacuum at low temperature is applied for the concentration of juices or solutions and the removal of residual moisture from liquid products.

Degassing

Air in soft drinks and water, as well as in viscous products, creates a problem with the homogeneity and purity of the material and may cause oxidation of the product. Air is usually removed with the help of liquid ring vacuum pumps.

Filling/closing machines

When filling containers and bottles, the air slows down the process and must be removed by means of liquid ring vacuum pumps. When closing the package, the remaining air above the product must also be removed by means of vacuum pumps, to prevent oxidation and ensure long product life.

Packaging under vacuum

Products such as sausages, cheese, coffee, nuts, etc. are packaged in vacuum to remain fresh until the date of consumption. The vacuum is created by rotary vane vacuum pumps or multi-stage vacuum units with high vacuum screw pumps.

Special pumping applications

Special pumps for liquids and viscous or delicate products are available, usually in stainless steel and, where appropriate, in special food-grade design and in place cleaning (CIP). Progressive cavity pumps or peristaltiv pumps are mostly used for viscous products, dosing pumps are applied for additives and chemicals. Centrifugal pumps with open impeller are ideal for pumping of high flow rates of sugar solutions, juices, fruit transportation, etc.

Pasta industry

Vacuum is required to remove air bubbles and achieve a visible and homogeneous product and has to be applied at the extruder by means of liquid vacuum pumps working with water or oil in closed air cooled circuit.

Pasta industries also widely use semolina pneumatic conveying systems with lobe blowers.

Flour/Bakery/Pastry

Pneumatic conveying of flour and sugar is widely applied, mostly with lobe blowers and side channel blowers in smaller scale applications. Lobe blowers are also used for the silo filters’ cleaning process.

Fermentation processes

For the production of yeast, or other similar products, fermentation takes place in aerated tanks by means of large quantities of air from lobe or screw blowers.

Poultry / fish processing

Liquid ring vacuum pumps are widely used in the processing of poultry and fish, and in particular in the process of gutting, the removal and collection of viscera with special vacuum nozzles.

Refining of edible oils

With the help of our specialized partners we provide solutions for crude oil filtration, bleaching under vacuum, bleaching earth filtration, steam deodorization with multistage high vacuum systems, final polishing filtration and filtration for wax removal(winterization).

Dairy products

Wide use of liquid ring vacuum pumps for the production process and high vacuum rotary vane vacuum pumps for packaging.

Dosing and progressive cavity pumps for creams, yoghurts.

Wastewater treatment/biogas

Most food industries, and especially those with liquid waste, produce very high pollution loads, which demand a large scale wastewater treatment plant. The most critical part of the plant is wastewater aerationinvolving blowers and membrane aeration systems, chemical dosing pumps and progressive cavity pumps for sludge.

Where applicable, waste sludge can be anaerobically digested, resulting in biogas production a vauable source of electrical and thermal power. Our company supplies a wide range of products in such plants, incLuding biogas blowers, digester equipment, biogas storage, desulfurization, drying and flaring.